Development for the Next Generation

We aim to supply new value through materials and contribute to the society of the future.

Next Generation Development

1.Hydrogen and Carbon Nanotubes (CNTs) Synthesis Using the Direct Methane Reforming (DMR) Method

Decarbonisation efforts accelerate in and out of the country. When hydrogen does not emit the greenhouse gas carbon dioxide (CO₂) during its production process, it is clean energy which pay attention to stable supply and reduce environmental impact.

We focus to the DMR method producing hydrogen and solid carbon material from hydrocarbon such as methane, and work on developing an efficient production process which produce hydrogen and CNTs by using a high activity iron catalyst.

- The DMR method

-

-

Reaction formula

-

Diagram of the production process

- Hydrogen

-

- The hydrogen production process using the DMR method does not produce CO₂ emissions. In addition, the hydrogen can contribute to achieve a decarbonized society, because it is CO₂ emission free, when it is used as a fuel of thermal power or thermal energy of burning it.

- Using Biomass fuel as a raw material of the DMR method is considered carbon neutral.

- We work on developing a high efficiency CO₂ emission-free hydrogen production process.

- Adoption for NEDO Advancement of “Development of Technologies for Realizing a Hydrogen Society”

-

TODA KOGYO Corp. and AIR WATER INC. have proposed "The building of regional CO₂-free hydrogen supply chain utilizing unused natural gas in Toyotomi Town in Hokkaido" in the "Development of Technology for Realizing a Hydrogen Society/Development of Regional Hydrogen Utilization Technology" public solicitated by the New Energy and Industrial Technology Development Organization (NEDO). Their proposal was adopted. We promote development of regional hydrogen utilization for achieving a carbon neutral society through this project.

- Carbon nanotubes (CNTs)

-

- Solid carbon produced as a byproduct of the DMR method can be produced in the form of carbon materials such as CNTs.

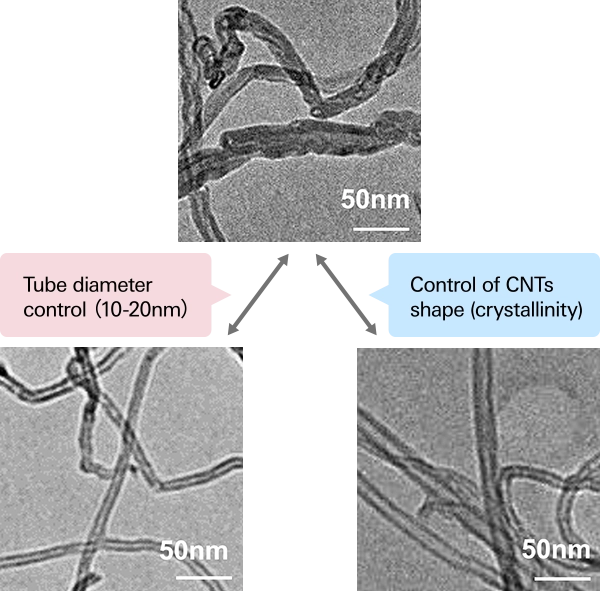

- CNTs are cylindrical structures rolled graphene sheets. Single-walled carbon nanotubes (SWCNTs) are made from one graphene sheet, whereas multi-walled carbon nanotubes (MWCNTs) are made from several graphene sheets. CNTs are from several nanometers to several tens of nanometers in diameter and several tens of micrometers in length.

- CNTs have been promoted their applications in a wide range of fields such as a conductive additive for lithium-ion batteries, a conductive filler, a reinforcement material and an electromagnetic wave absorption material because of the remarkable properties(i.e., low weight, high strength, high electrical conductivity and high thermal conductivity).

- CNTs easily become entangled aggregates. Therefore, a high dispersion technology is necessary in order to show their potential functions.

- We develop high-added value multi-walled CNTs by using a catalyst and process technology.

- Representative physical properties

-

TC-2000 Type Tangled Avg. tube diameter (nm) 16 Length (μm) 1-5 Purity (%) >91 Bulk density (g/cm³) 0.05-0.10 Crystallinity IG/ID 0.9-1.3 - Comparison of dispersibility

-

- CNTs control technology

-

-

It’s not possible to provide a sample in some cases of use purposes because of under development.

2.Soil and Groundwater Remediation Agent

Soil and groundwater polluted with hazardous substances such as volatile organic compounds (VOCs) and heavy metals affect human health, growth of agricultural crops and plants and ecosystems. Moreover, residual hazardous substances cause a long-term pollution in the original area and can result in further pollution over large areas by leaching into groundwater. Therefore, we must take measures to prevention of pollution diffusion and degradation and removal of pollutants.

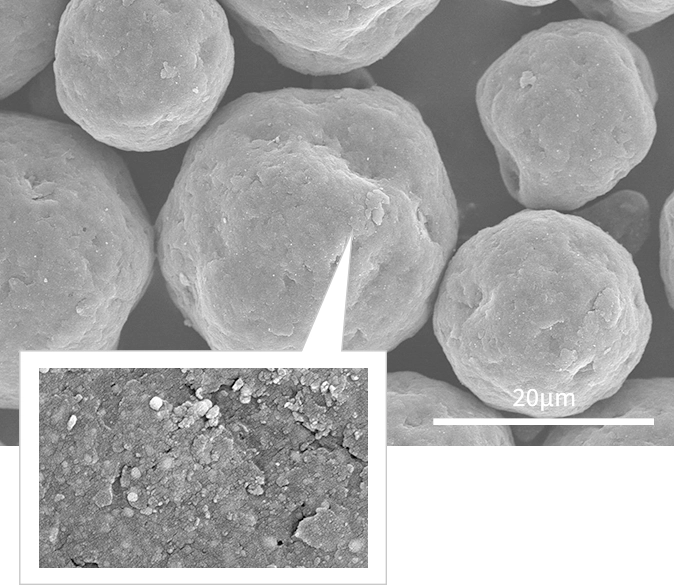

We work on developing soil and groundwater remediation agent to solve these problems. Our sample under development is a high activity material in which iron nanoparticle (α-Fe) is highly dispersed in a carbon matrix. Therefore, it is an innovative Iron nanoparticle-carbon composite that can be applied to in-situ remediation of polluted soil and groundwater.

- Composite material structure

-

-

- Iron nanoparticle (10-100nm) containing α-Fe highly dispersed in a carbon matrix

-

-

- Trichlorethylene (TCE) decomposition

-

- Our development sample is a strong reducing agent. Therefore, chlorine atoms are replaced with hydrogen atoms, i.e., the VOCs decomposition.

- The TCE decomposition rate is 100 times faster than the existing iron powder.

- It achieves higher TCE decomposition than our product RNIP™ (α-Fe+Fe₃O₄).

The mock-polluted water samples (it is about 5,000 times TCE concentrations than the soil elution standard prescribed to the Soil Contamination Countermeasures Act) were analyzed using gas chromatography and evaluated the change of TCE concentration with reaction time by addition of the remediation agent.